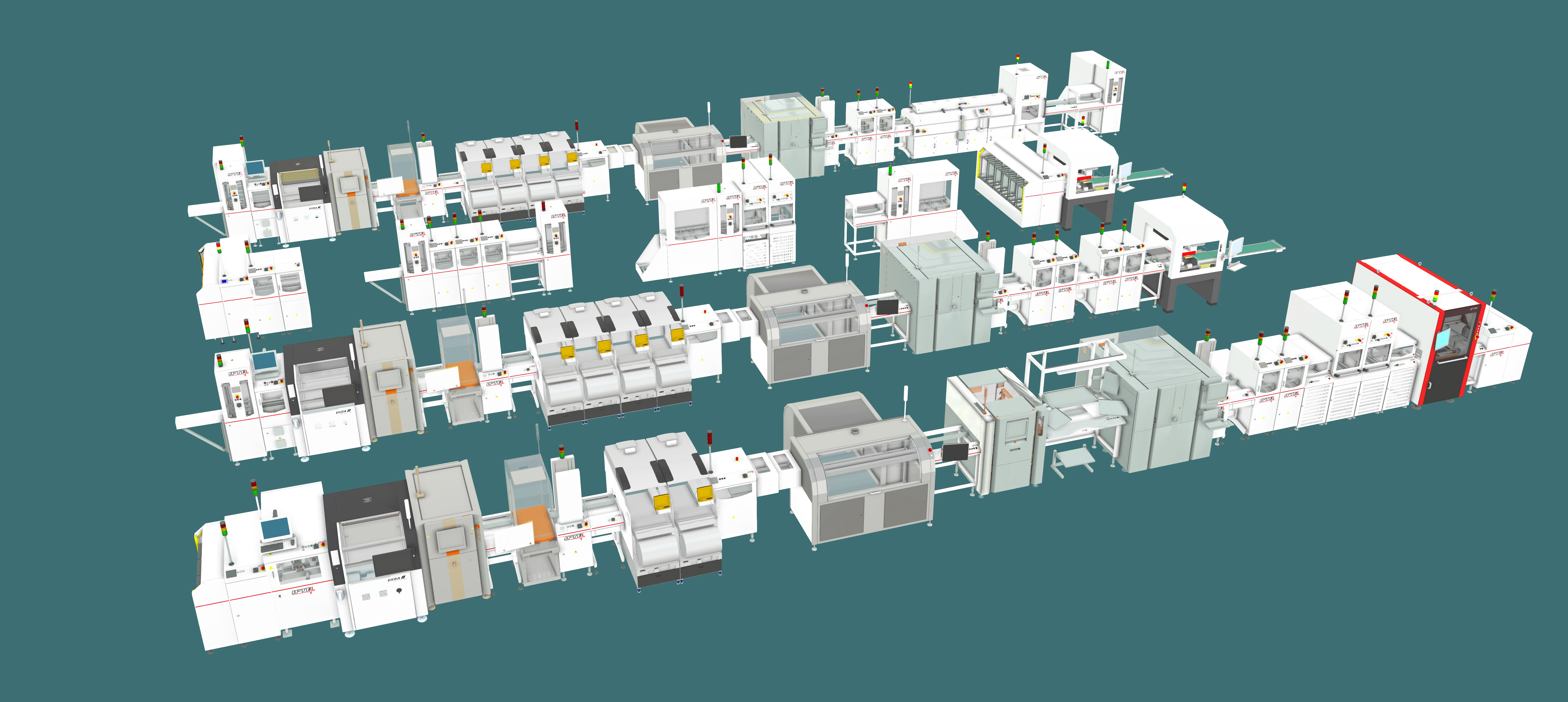

SURFACE MOUNT TECHNOLOGY

IPTE engineers and draws up the full range of depanelling machines, single pin insertion machines for press fit applications and high force connector placement machines, palletizer and all special component feeders.

Covering the spectrum from stand alone up to fully automated production lines for the SMT market.

-

Depaneling

Depaneling

IPTE Depaneling systems are designed to singulate individual images from a panel in a high speed, low stress process. The depaneling units are economical in footprint, cost, have an excellent return on investment and embrace all the latest concepts in lean design.

Go to products

-

Conveying

Conveying

IPTE's portfolio of the Easyline equipment includes all necessary modules for the efficient handling of boards in electronics manufacturing lines. In addition to the highest of demands on the quality and reliability of this equipment, the key targets for the design of the new handling-units program have been the maximum standardization of the modules, as well as of the software and of the operation mode.

Go to products -

Marking

Marking

IPTE provides both laser and labeling cells for direct marking onto board assemblies or products. The laser system can write conventional bar codes, 2D data matrix codes and images followed by an optional verification check.

go to products -

Feeding

Feeding

IPTE provides a wide range of standard (e.g. radial, axial, tube, tray) and customized feeders that covers the majority of currently available odd-shaped components to complement the flexibility of the odd-form-placement system.

Go to products

-

Scanning

Scanning

IPTE provides standard solutions for scanning 1D and 2D codes on PCBs.

go to products -

Laser Plastic Welding

Laser Plastic Welding

The basic principle of Laser Plastic Welding (LPW) is laser energy that passes through a transmissive top layer and reaches an absorptive bottom layer. The heat created by the laser energy will melt the materials. The result is a superior weld joint after the material cooled down.

Go to products -

Sawing

Sawing

-

Pallet handling

Pallet handling

In high volume assembly lines requiring continuous material flow with flexibility, pallet based systems offer the optimum solution.

Go to products -

Odd Form Placement

Odd Form Placement

With IPTE Odd From Placement products (e.g. relays, fuse holders, transistors or electrolytic capacitors) can be placed into PCBs with maximum flexibility and quality due to different gripper types with automatic exchange and process control functions like pin height and concentricity checks.

Read more -

Pin Insertion

Pin Insertion

IPTE provides super-fast and force controlled pin insertion processes for needle and plane pins with cycletime up to 2.6s per pin, automatic coil feeding with zero exchange time and optical process inspection to speed up the automatic production flow.

-

Press fit

Press fit

IPTE offers innovative, powerful and flexible press-fit solutions for almost every customer application. IPTE’s new and proven production cell is now available.

go to products -

Test Handling

Test Handling

IPTE Test Handling systems are designed to facilitate the automated testing of PCBs in an in-line or stand-alone process. The handlers are economical in footprint and cost, give an excellent return on investment and embrace all the latest concepts in lean design.

Each welded steel framed unit is fully equipped with its own control and diagnostics via a user friendly interface. The units are fully compatible with other SMEMA units and other standard equipment in electronics manufacturing lines to ensure a truly 'plug and play' assembly line strategy. Fixture exchange can be carried out in seconds to ensure minimum downtime.

Read more -

Soldering

Soldering

IPTE now supplements their equipment portfolio with a selective wire soldering production cell especially directed at demanding soldering processes on PCBs, hybrid ceramics, flexible film materials and many more substrates.

Go to products -

Screw Insertion

Screw Insertion

IPTE integrates Screwing Heads of several suppliers into standard machines to realize fully automatic or half-automatic screwing processes with different screw types (e.g. shear head bolts) and process control functions like torque and angle control.

-

Dispensing

Dispensing

IPTE integrates Dispensing Heads of several suppliers into standard machines to realize fully automatic 2D or 3D Dispensing processes with different components (1K and 2K) and calibration routines like needle measurement or material scaling.