Short cycle time

You can customize the FlexMarker II with following features to minimize the cycle time of the laser marking proces.

-

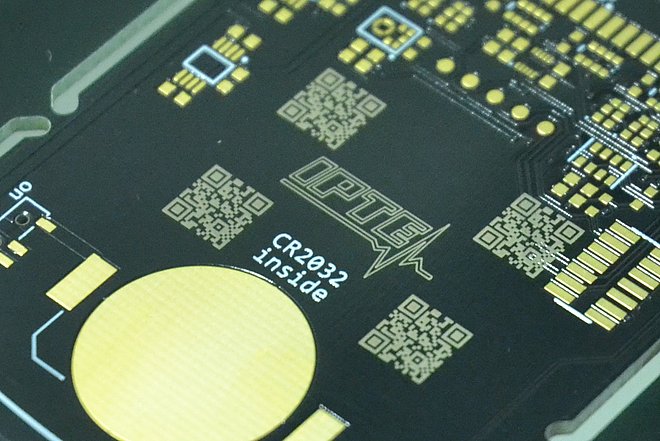

Verify@Once

Verify@Once

After the Laser@Once feature has marked multiple codes within a large field of view of 90 x 90 mm. It's now possible to do the verification of all markings in that same area with the Verify@Once option.

-

Synchronized Transport

Synchronized Transport

To reduce cycle time, PCB transport plays a major role. Allowing processes to take place simultaneously during PCB import and export, you gain vital seconds.

-

Integrated Flip

Integrated Flip

By equipping the FlexMarker II with an integrated flip unit, you not only save space, you also gain cycle time. On the one hand, because you no longer need an external Flip unit. On the other hand because the laser can already take position during the flip movement.