To ensure that electronics used for high-power applications meet the strictest quality standards, extensive testing is essential. Thanks to our comprehensive experience in test engineering, we were able to develop a compact, yet performant stand-alone test station for our client to perform long-term burn-in tests on a DC/DC Converter.

There are a number of challenges in this project. First, there are our client's testing needs. He wanted to perform burn-in tests of 1.5 hours under high voltage. These kind of tests require liquid cooling, which immediately posed a new challenge. Furthermore, floorspace had to be used efficiently. This was because it was limited. And finally, the test station had to be suitable for multiple, different applications.

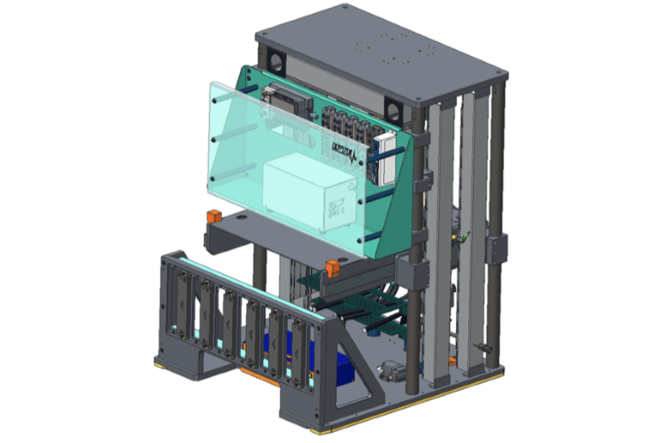

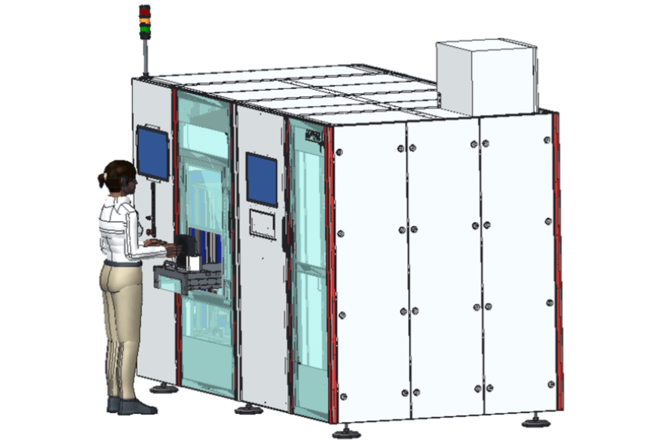

Our solution consists of a compact cell of just 5.7m². Embedded are all the necessary elements - fixture, instrument rack, test area and cooling system - for performing burn-in tests. Our easy-to-use software TS1 controls the entire process and gives the operator all tools necessary to manage the settings of the test station. Thanks to the flexible design, it’s easy to switch to another application such as an On-board Charger (OBC), Invertor or Battery Monitor System (BMS).

After manual loading of the DUT, the electrical and hydraulic connectors automatically make contact with the DUT. Then the station performs a Leak test to check if no cooling liquid is leaking. After that a HIPOT test, High Voltage test and Low Voltage test will be executed. Standard with CAN communication and up to 30Kw, but capable of reaching 100Kw.

Since 1992, IPTE empowers businesses with reliable automation solutions. Curious about how we can take your manufactoring and testing processes to the next level?